Project Overview

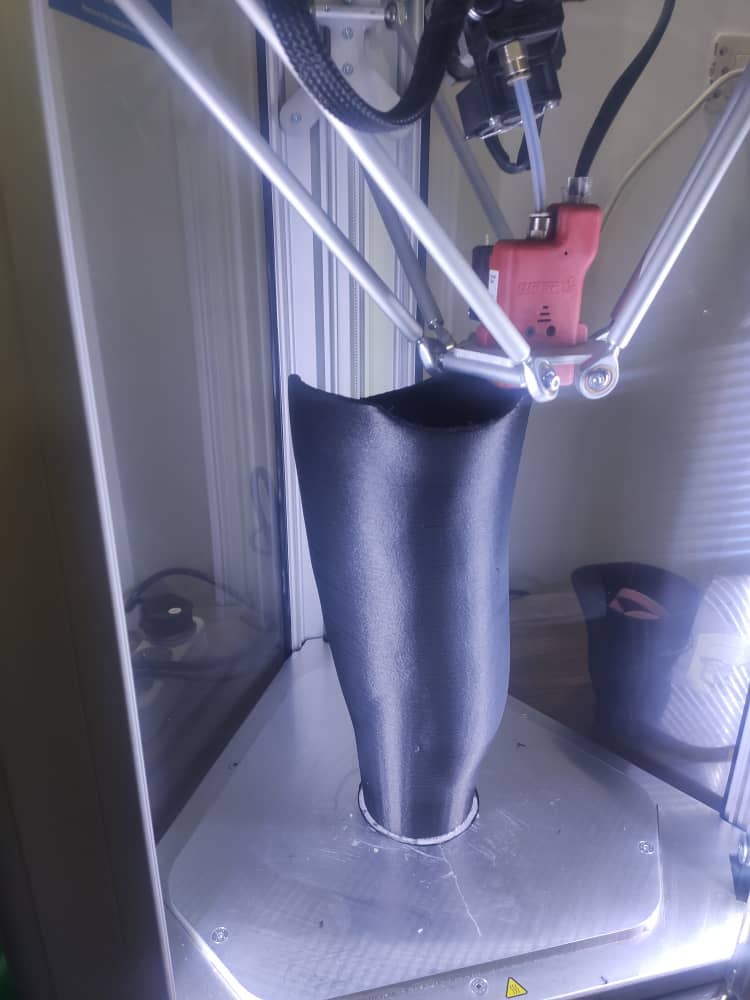

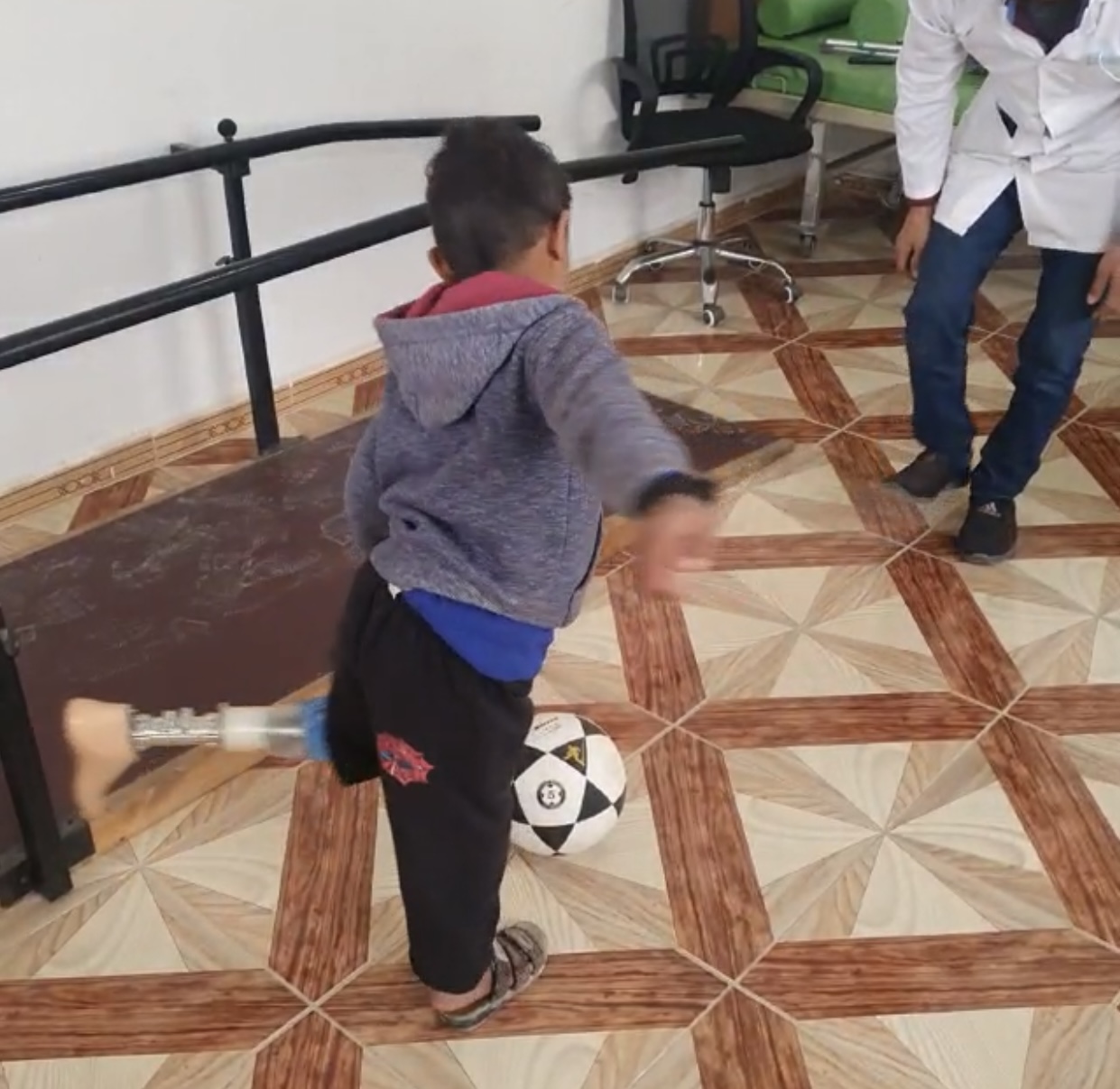

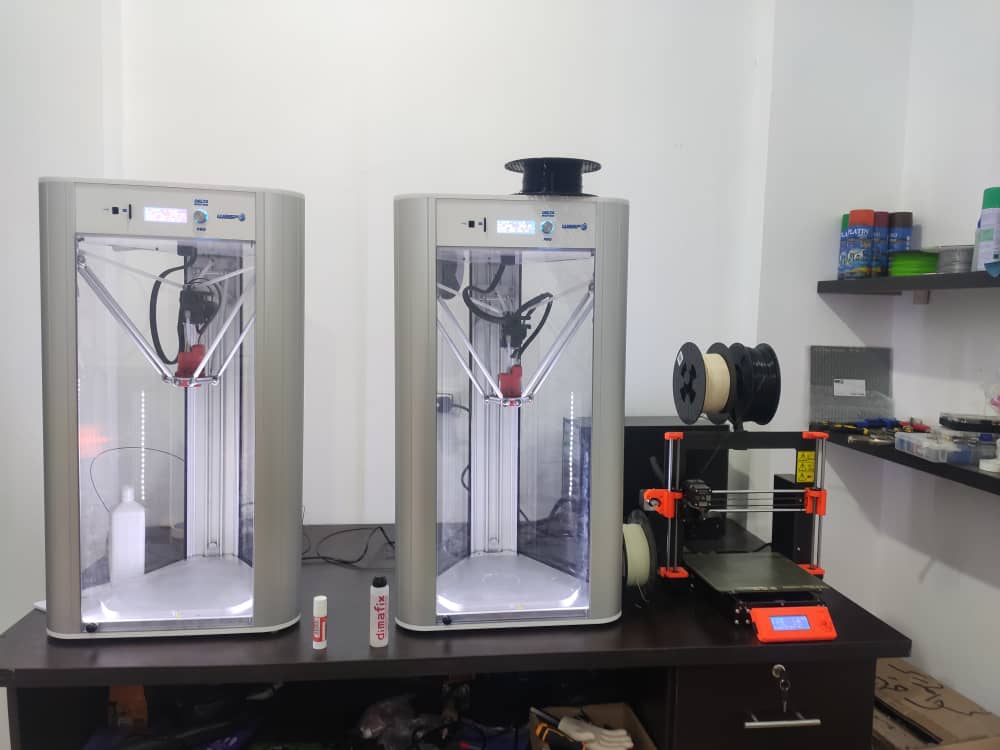

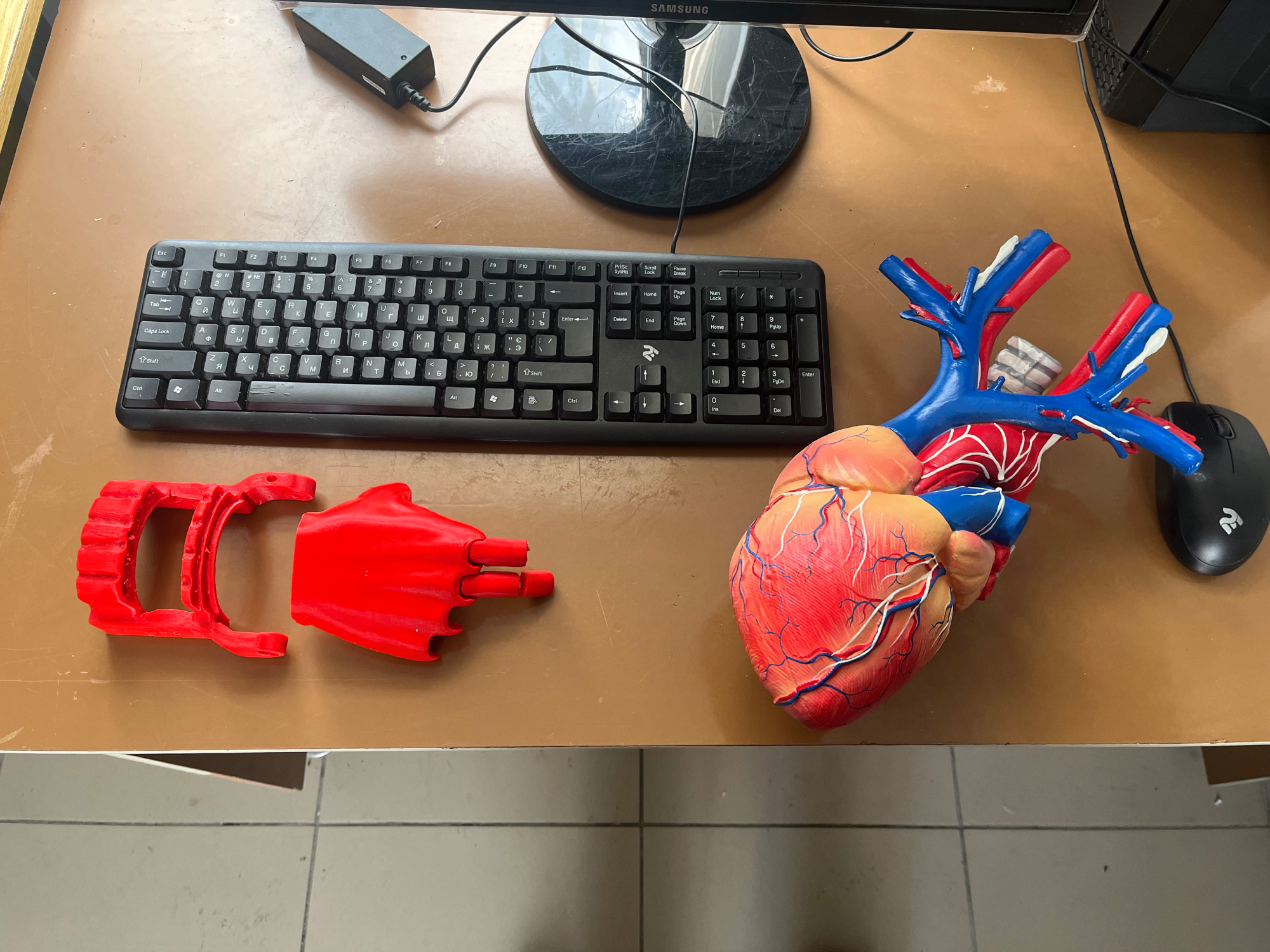

Since 2021, The Heracles Group has shown that a small, digitally-driven prosthetics lab can transform lives in Northeast Syria (NES). By pairing handheld 3-D scanners with 3D printers, the pilot site inside Raqqa National Hospital leapt from crafting 5–10 traditional limbs per month to producing a custom, ergonomic prosthesis every 24 hours. Building on that success, Heracles opened parallel micro-labs in Al-Hasakeh and Abu Hamam, giving 5 million Syrians their first realistic path to affordable limbs, physical-therapy coaching, and follow-up care. The initial NES rollout is fully funded and complete; we are now inviting new donors to help replicate the model across Syria and subsidize limb costs for patients in need. With the NES model now validated, Heracles seeks to scale the network—adding hubs in every Syrian governorate, linking them into a supply-chain and training ecosystem that turns local clinicians into digital-fabrication specialists while slashing wait-times for amputees nationwide.

The problem

Over 100,000 Syrians lost limbs during the ISIS conflict and the Syrian civil war, yet outside NES barely a handful of clinics exist—and most rely on slow, supply-starved, hand-cast methods. Thousands remain immobile, jobless, and socially isolated while explosive remnants of war continue to create new amputees each year.

Our Solution:

- Digital-first clinics in every region: Structure Sensor Mk II scanners + Ossur Design Studio + 3D printers.

- Local talent pipeline: certify Syrian prosthetists, design technicians, and physical-therapy aides in six-week bootcamps.

- 24/7 production cadence: each printer yields ~250 limbs per year; modular fleets scale with demand.

- End-to-end care: on-site rehab suites teach gait, balance, maintenance, and community reintegration.

Impact: “Mobility Restored, Futures Reclaimed.”

- 4× production jump: from 120 conventional limbs/year to 500+ digital limbs/year per hub.

- National reach: ≤ 150 km average travel distance for any amputee in Syria.

- Economic uplift: patients regain capacity to work; technicians gain high-value careers.

- Sustainable system: locally sourced filament & spare parts, reducing import dependency and costs by 40%

Funding Status & Call for Support

- The Northeast Syria phase (three micro-labs) is fully funded and operational.

- To extend this success nationwide and underwrite no-cost limbs for the most vulnerable, Heracles welcomes additional partners and donations.

Future Needs — “Scaling Syria, Leaving No One Behind.”

- Nationwide coverage: replicate the NES micro-lab model in 7 additional hubs (Aleppo, Hama, Homs, Damascus, Daraa, Tartous, Deir ez-Zor) so that 90 % of amputees live within a two-hour journey of a prosthetic clinic.

- Equipment surge: deploy 24 more Prusa printers, 10 Structure Sensor scanners, and one mobile fitting truckfor hard-to-reach villages.

- Human-capital pipeline: train and certify 50 prosthetists, 60 design technicians, and 30 physical-therapy aidesthrough an intensive, locally led apprenticeship program.

- Patient Mobility Fund: seed a $500 k subsidy pool to cover up to 100 % of limb costs for uninsured or low-income patients—enough to underwrite roughly 1,200 prostheses in the first year.

- Sustainable supplies: establish a regional filament-extrusion partnership that cuts per-limb material costs by ≈ 35 % and buffers against import disruptions.

- Data & quality assurance: roll out a national patient registry, remote follow-up via tele-rehab, and outcome-tracking dashboards to guide continual improvement.

- Policy & advocacy: work with the Syrian MoH, WHO, and disability-rights NGOs to have 3-D printed limbs recognized and reimbursed under public insurance schemes, ensuring long-term affordability for all.