Project Overview

Entering its fourth year, the war in Ukraine has produced a scale of limb loss unseen in Europe since WWII—≈ 50,000 amputees to date and many more expected as 2 million mines and daily artillery continue to seed explosive remnants of war (ERW). Drawing on its field-tested model from Northeast Syria, The Heracles Group (THG) is partnering with prosthetic clinicians, engineering schools, and a Kyiv-based manufacturer to plant a fully Ukrainian, 3-D-printed prosthetics ecosystem.

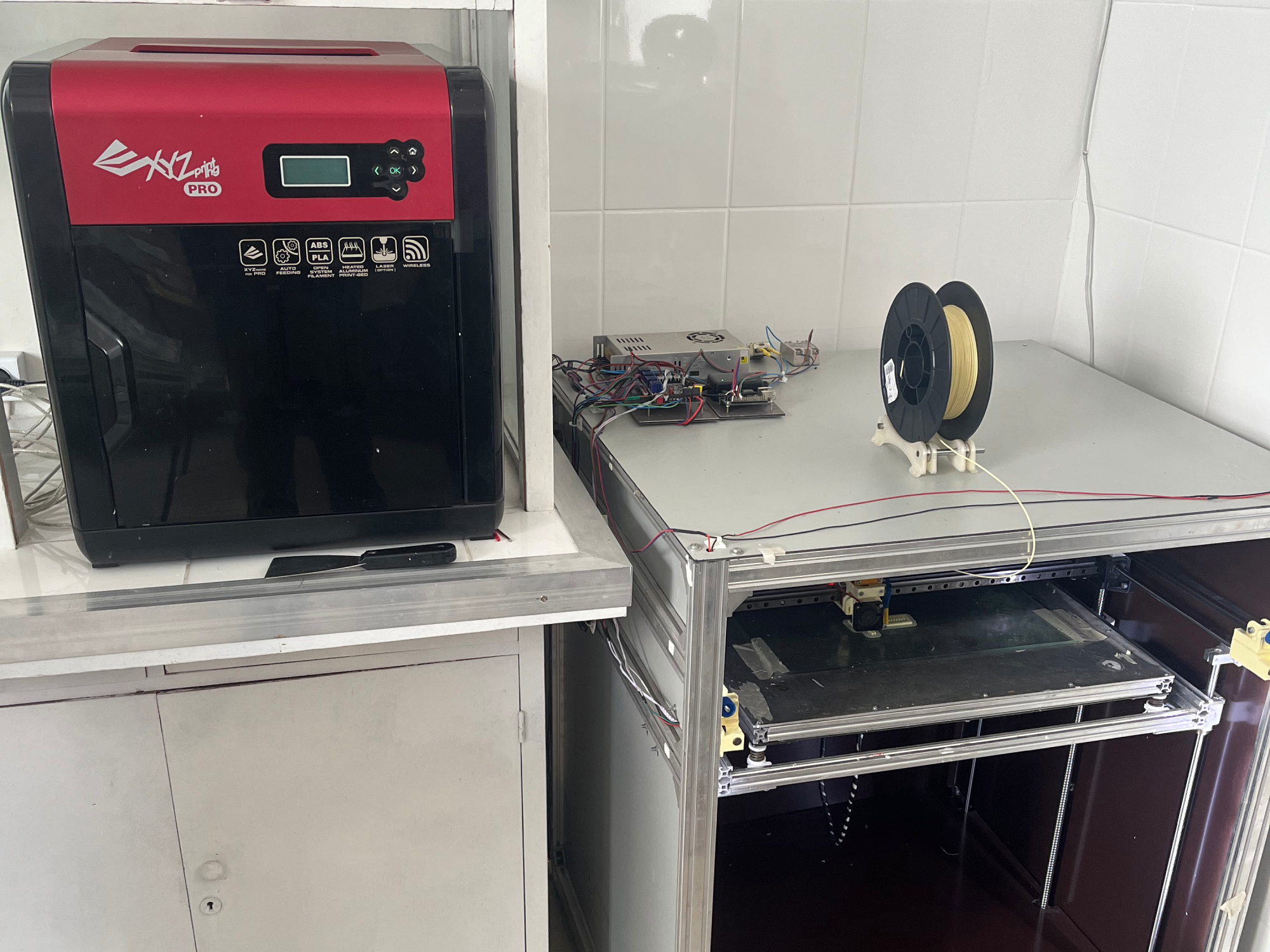

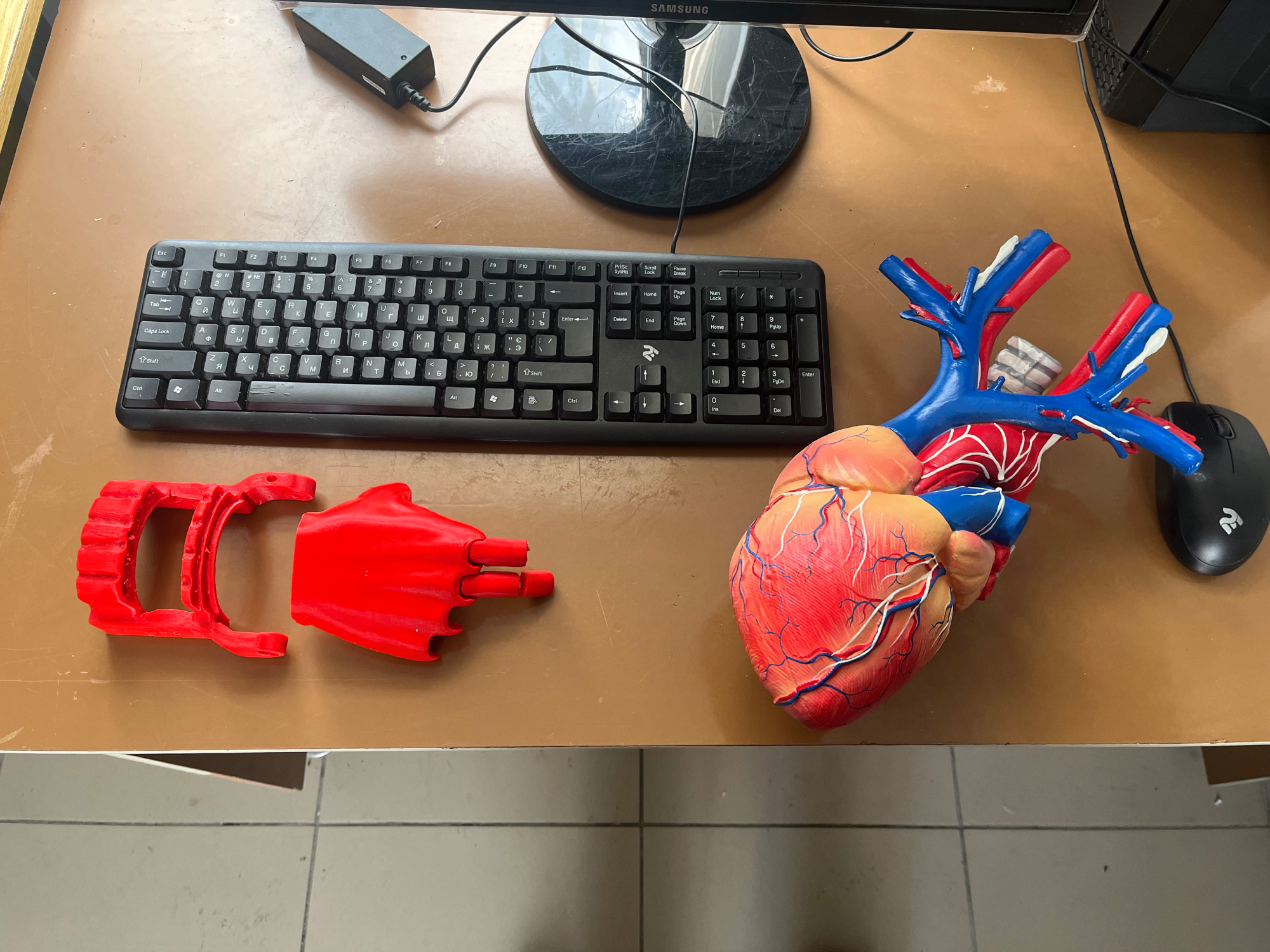

Our pilot—centered on Lviv National Medical University and Igor Sikorsky Kyiv Polytechnic Institute—pairs classroom instruction in 3-D scanning/printing with factory-floor retrofits, so students and technicians co-design, fabricate, and fit advanced limbs without relying on costly imports.

The problem

Conventional socket casting is slow, labor-intensive, and hostage to disrupted supply chains. Imported components can cost 2–3 × the average Ukrainian salary, and countrywide there is an acute shortage of prosthetists and physical therapists trained on modern tools. Without new capacity, tens of thousands of civilian and veteran amputees face multi-year wait-lists and prohibitive prices.

Our Solution — “Scan. Print. Walk.—Ukraine.”

- University Tech-Hubs: equip two academic fab-labs with 3D scanners, 3D printers, and associated design sofware.

- Talent Pipeline: certify 60 prosthetists & 80 biomedical/IT students each year in digital design, socket biomechanics, and printer maintenance.

- End-to-End Care: integrate on-site physio suites and remote-fit telehealth to reach amputees in front-line Oblasts.

Impact — “Mobility Made in Ukraine.”

- Local supply chain: 70 % of limb components sourced or printed domestically within 18 months.

- Cost cut by ≥ 40 %: transtibial limb price drops from ≈ €3,000 import to ≈ €1,700 local print & hardware.

- Capacity jump: pilot sites able to deliver 1,200 custom limbs annually, slashing wait times from months to weeks.

- STEM boost: hands-on R&D experience for medical, mechanical-engineering and computer-science students, fostering Ukraine’s next biomedical sector.

Future Needs — “Scaling the Print-Care Network.”

- Regional rollout: launch 5 satellite print labs (Kharkiv, Dnipro, Odesa, Vinnytsia, Zaporizhzhia) to place 90 % of amputees within 150 km of a digital clinic.

- Mobile Scan Units: deploy 3 van-mounted scanners & gait-analysis rigs for veterans in remote communities.

- Continuous QA & R&D: fund master’s fellowships to refine lightweight lattice sockets and AI-guided fit algorithms.

Funding Status & Call for Support

- Pilot phase funded: THG is securing equipment for two university hubs and one industrial line.

- Gap to scale: €6 M needed over three years to cover regional labs, mobile units, subsidies, and R&D fellowships.

Investors, foundations, and diaspora groups are invited to sponsor specific labs, student cohorts, or the national Patient Assistance Fund